Your partner for LPG solutions

Your partner for LPG solutions

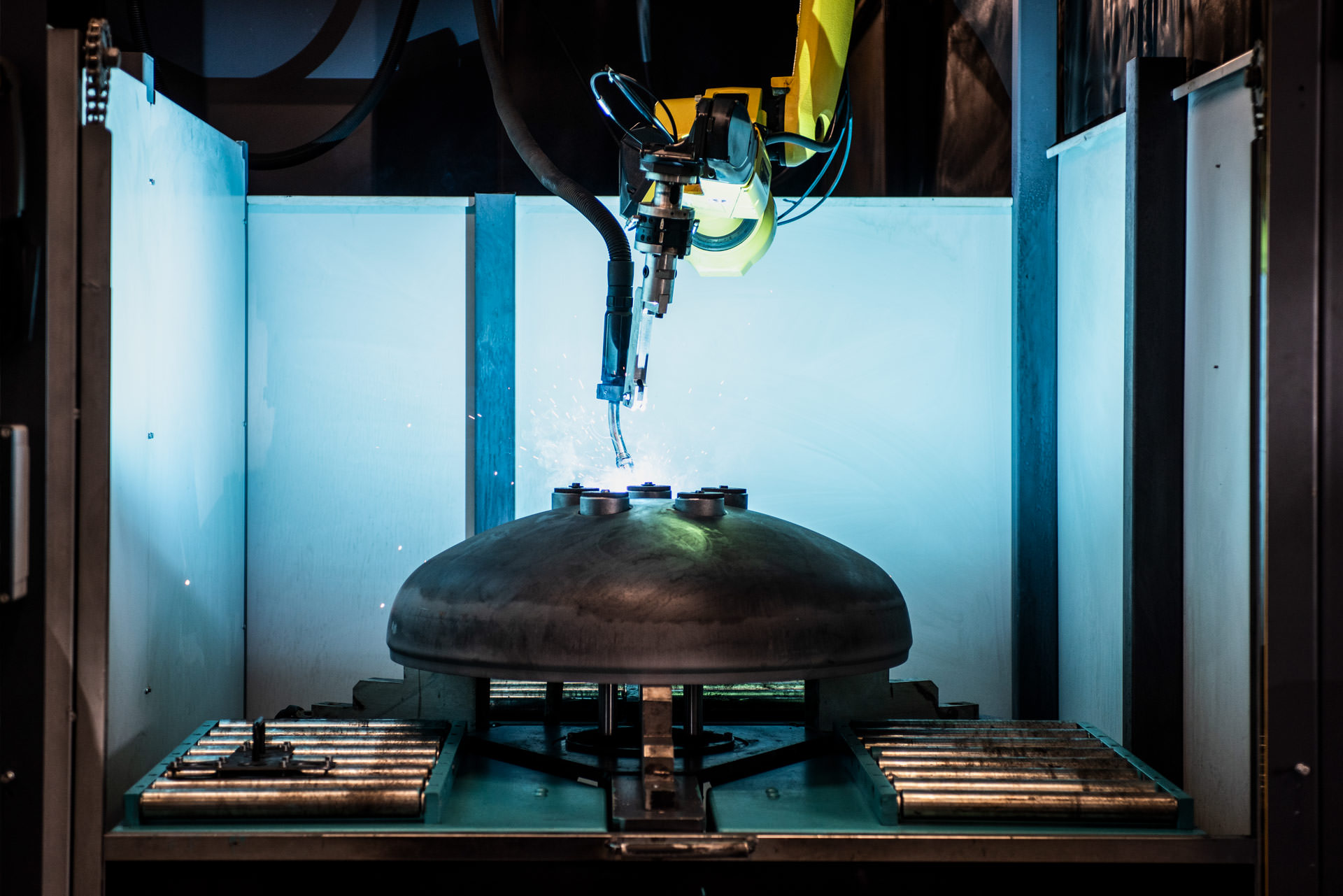

Product Verification and Quality Control

COATING APPROVAL

Pressure vessels must be protected against external corrosion from atmospheric exposure through the application of a protective coating system. This protective system must necessarily take into account the operating environment in which the pressure vessel will operate.

Checking the thickness of the wet coating

Thickness measurement is carried out during the coating cycle using the comb thickness gauge.

Measurement of dry coating thickness

Thickness measurements are carried out in accordance with current regulations, using a digital thickness gauge with built-in probe and a measurement kit containing a reference thickness for initial instrument calibration and zeroing.

Verification of adherence

The coating adhesion test is a test used to assess the resistance of coating layers to detachment from sub-layers. For above-ground tanks it is carried out by means of an incision all the way down to the metal support.

For underground tanks the adherence test is carried out using the PULL-OFF method which measures the force of detachment of a coating from its metal base support.

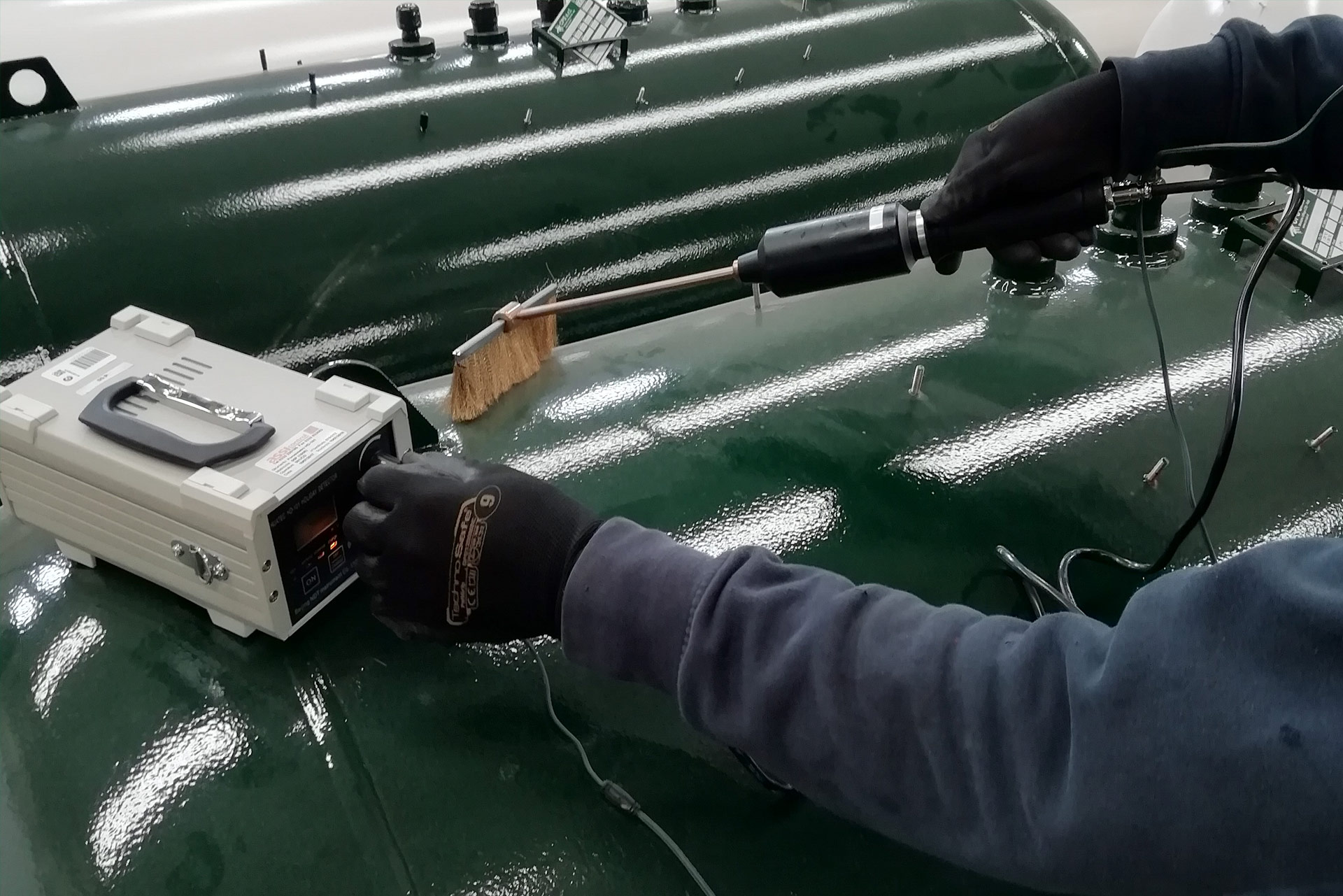

Verification of electrical insulation

The insulation coating in passive protection of external surfaces of underground tanks is subject to chemical and electrochemical corrosion. Therefore, it is essential to check the coatings in order to ascertain their effective and safe execution. The porosity detector produces a few voltage pulses on the surface of the protective paint covering the tanks and allows the electrical insulation measurement value to be checked.