Technical Specifications

Your partner for LPG solutions

Standard Tanks Produced In Series

ranging from 0.3 cubic meters to 13 cubic meters

CPS srl can construct tanks according to specific national regulations upon request.

TECHNICAL SPECIFICATIONS

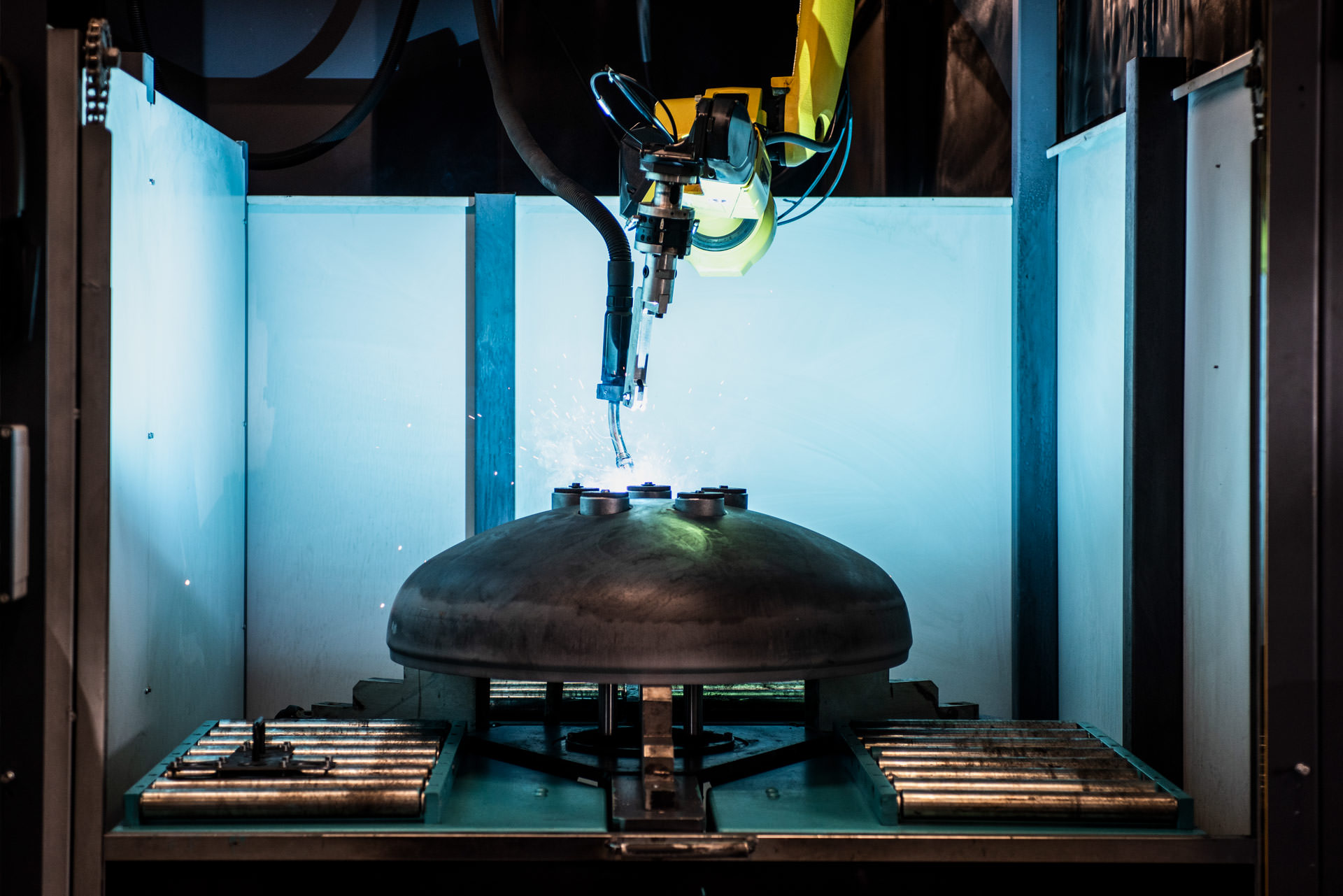

Construction Code: EN 13445-3

Approval: PED 2014/68/EU

Certification: CE in accordance with EN 17065

Category: IV

Shell and Head Materials: P355NH – UNI EN 10028-3

Material Certificates: EN 10204 – 3.1

Operating Pressure: 1,76 MPa – (2,0 MPa) (if requested)

Design Temperature: -20 °C +50 °C

Hydrostatic Test Pressure: 25.24 bar – (30.00 MPa) (upon request)

Contained fluid: LPG

Welding coefficient: 1 – (0,85) (upon request)

Safety coefficient: 2,4 – (2,7) – (3,0) (upon request)

INSPECTIONS, TEST AND ACCEPTANCE

Compliant with PED, EN 12542, and EN 13445

NDT: UT, VT, PT, (RT) (upon request)

FINISHING

External protection of the tank through a surface finishing that ensures corrosion protection:

A) ABOVE GROUND TANKS

Sanbdblasting grade SA 2,5

High zinc content polyurethane. Thickness: 120 microns

B) UNDERGROUND TANKS

Sanbdblasting grade SA 2,5

Two-component epoxy paint. Thickness: 500 microns

Alternative solutions can be provided to cater to specific consumer requirements.

SUPPLIES

Cathodic Protection Kit (for underground tanks)

Safety and Service Accessories

CE Declaration of Conformity