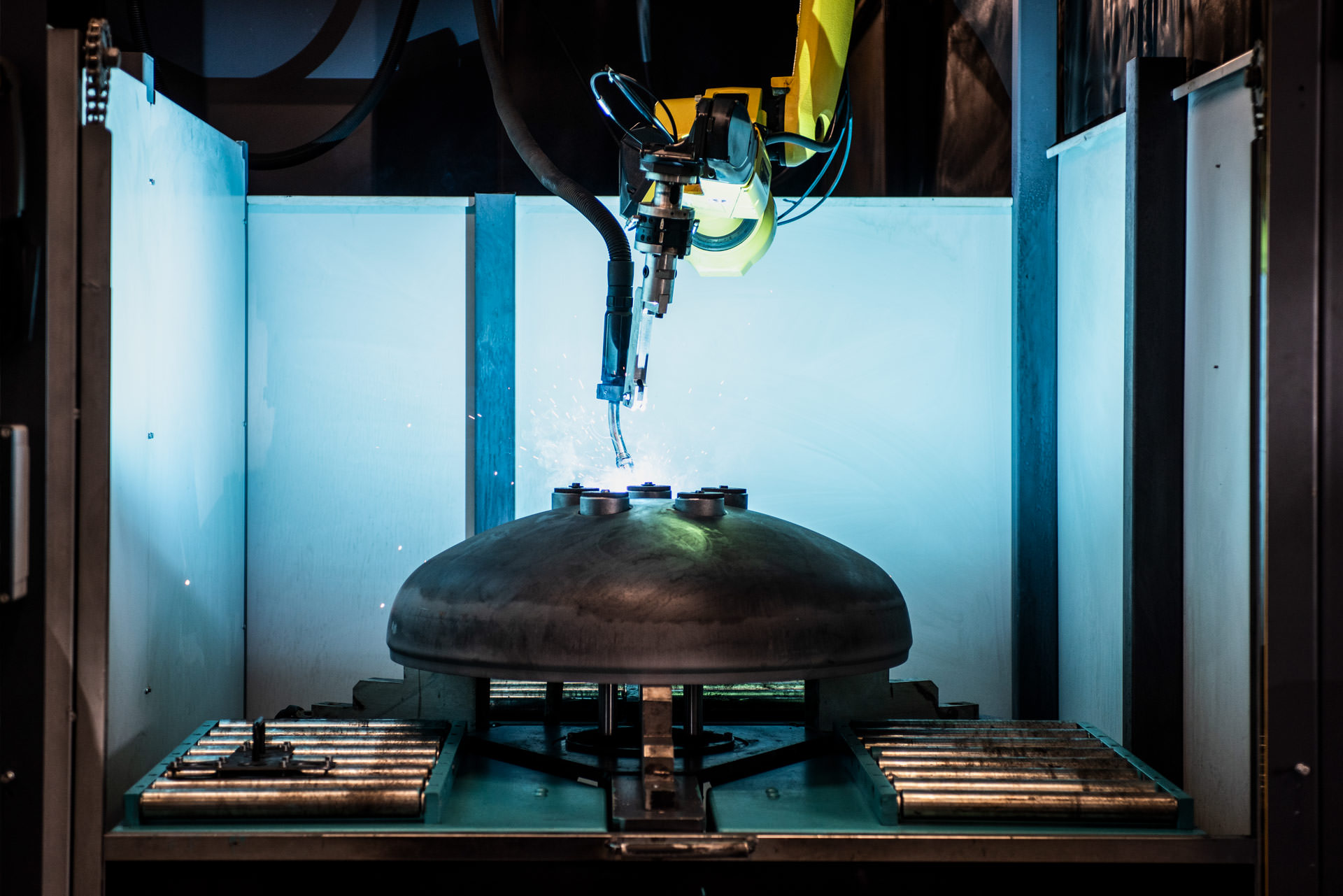

Your partner for LPG solutions

Your partner for LPG solutions

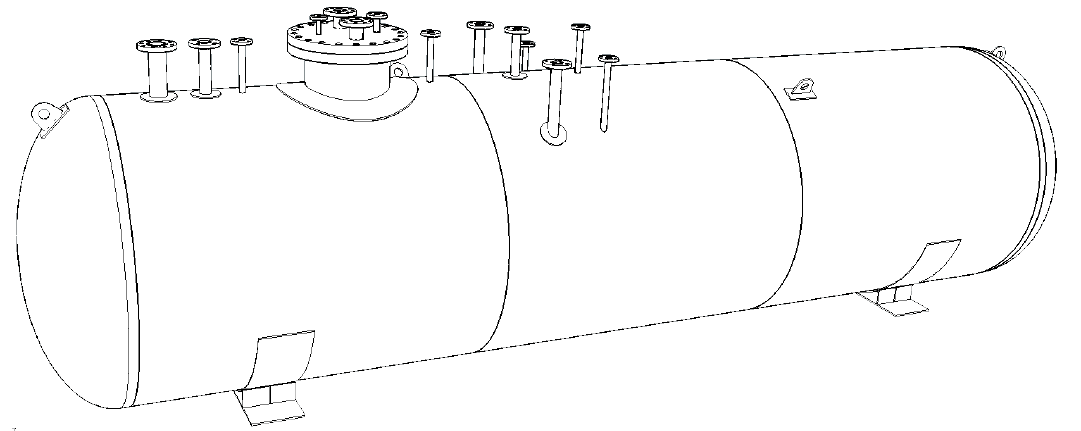

LPG TANKS FOR SERVICE STATIONS FOR BURIED OR CONTAINING CASE INSTALLATION

PED 2014/68/EU

CAPACITY: 15 – 20 – 25 – 30 – 35 – 50 MC

TECHNICAL DETAILS

Construction Code: EN 13445-3

Approval: PED 2014/68/EU

Certification: CЄ in accordance with EN 17065

Category: IV

Shell and Head Materials: P355NH – UNI EN 10028-3

Material Certificates: EN 10204 – 3.1

Operating Pressure: 17.65 bar – (20,00 bar) (if requested)

Design Temperature: -20 °C +50 °C

Hydrostatic test Pressure: 25,24 bar – (30,00 bar) (upon request)

Contained fluid: LPG

Welding coefficient: 1 – (0,85) (upon request)

Safety coefficient: 2,4 – (2,7) – (3,0) (upon request)

INSPECTIONS, TESTS AND ACCEPTANCE

Compliant with PED, EN 12542 and EN 13445

NDT: UT, VT, PT, (RT) (upon request)

FINISHING

External protection of the tank through a surface finishing that ensures corrosion protection:

Sandblasting grade SA 2,5

Two-component epoxy paint. Thickness: 500 microns

Alternative solutions can be provided to cater to specific consumer requirements.

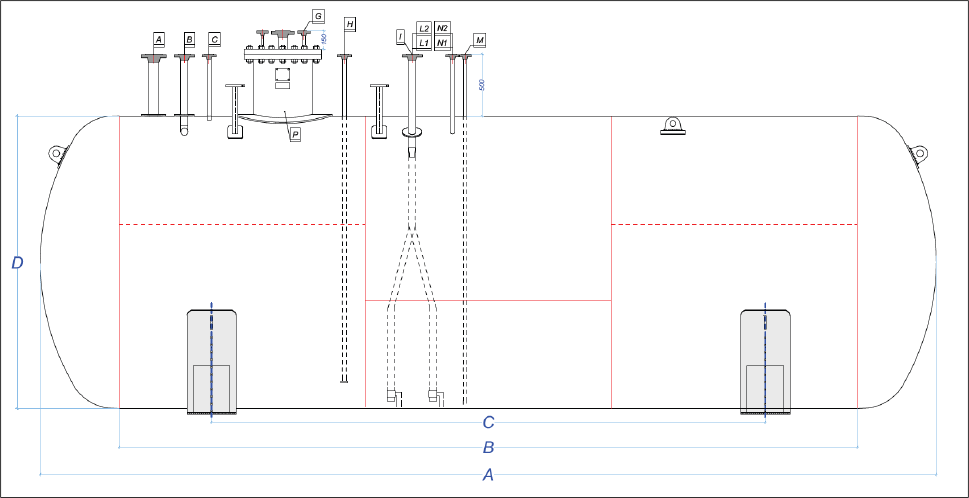

DATA SHEET

| PRODUCT CODE [TUM_STAZ : Buried] [CAS_STAZ : Containg case] | C.tà [mc] | A [mm] | B [mm] | C [mm] | D [mm] |

| NCVTUM_STAZ_15MC-OR | 15 | 6.940 | 6.000 | 4.500 | 1.700 |

| NCVCAS_STAZ_15MC-OR | |||||

| NCVTUM_STAZ_20MC-OR | 20 | 5.300 | 4.000 | 2.500 | 2.370 |

| NCVCAS_STAZ_20MC-OR | |||||

| NCVTUM_STAZ_25MC-OR | 25 | 6.300 | 5.000 | 3.700 | 2.370 |

| NCVCAS_STAZ_25MC-OR | |||||

| NCVTUM_STAZ_30MC-OR | 30 | 7.300 | 6.000 | 4.500 | 2.370 |

| NCVCAS_STAZ_30MC-OR | |||||

| NCVTUM_STAZ_35MC-OR | 35 | 8.300 | 7.000 | 5.700 | 2.370 |

| NCVCAS_STAZ_35MC-OR | |||||

| NCVTUM_STAZ_50MC-OR | 50 | 12.300 | 11.000 | 4.750 (x2) | 2.370 |

| NCVCAS_STAZ_50MC-OR |

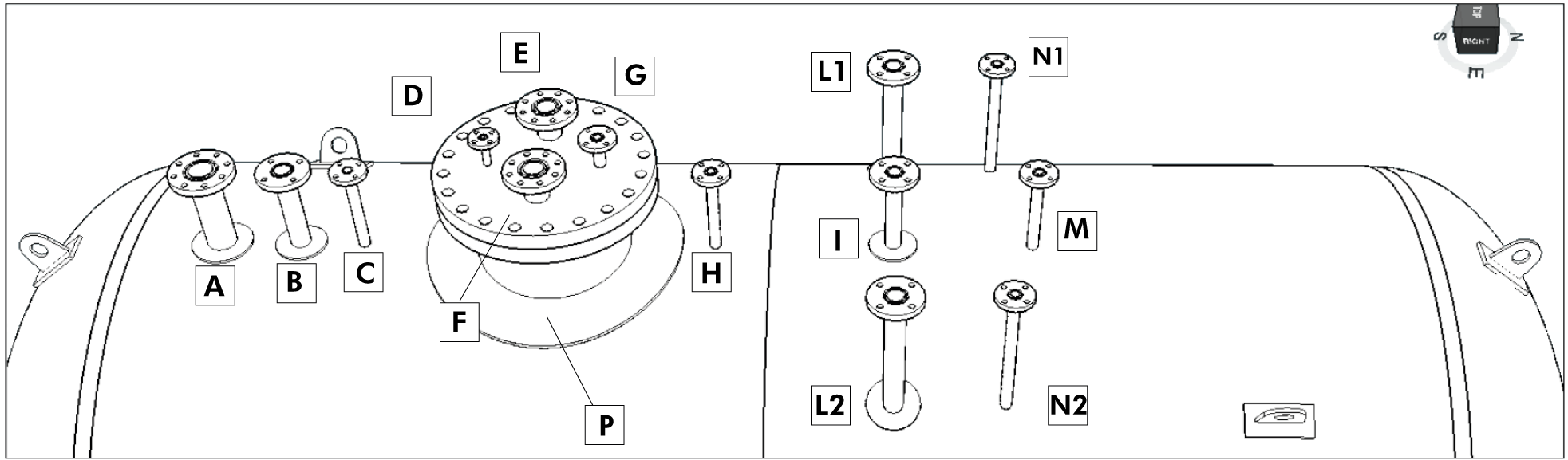

STANDARD CONNECTIONS

| ID | Nominal Flange Diameter | Function |

| A | DN 80 | Safety valves manifold |

| B | DN 50 | Filling |

| C | DN 25 | Gas phase withdrawl |

| D | DN 15 | Pressure gauge |

| E | DN 65 | Level Rod |

| F | DN 65 | Level gauge |

| G | DN 25 | Free connection |

| H | DN 25 | Thermometer |

| I | DN 40 | Dispenser return |

| L1 | DN 50 | Pump aspiration |

| L2 | DN 50 | Pump aspiration |

| M | DN 25 | Draining |

| N1 | DN 25 | Gas pump return |

| N2 | DN 25 | Gas pump return |

| P | DN 450 | Manhole |

EQUIPMENT ON REQUEST

Upon costumer request, tanks for service stations may be supplied with the following items:

a. Support staddle for pumps;

b. Enclosing support;

c. Cathodic protection:

n. 4 anodes of 8,5 kg with 10 mt cable + 1 electrode 150×300 (tanks of capacity up to 30 mc)

n. 6 anodes of 8,5 kg + 1 electrode 150×300 (tanks of capacity between 30 and 50 mc)

n. 1 steel plate with a 15 mt cable to be fixed to the tank

n. 25 mt cable for a ring connection

Please note that the installation of a cathodic protection system is strongly recommended, and shall be verified by the designer in function of installation place.