Your partner for LPG solutions

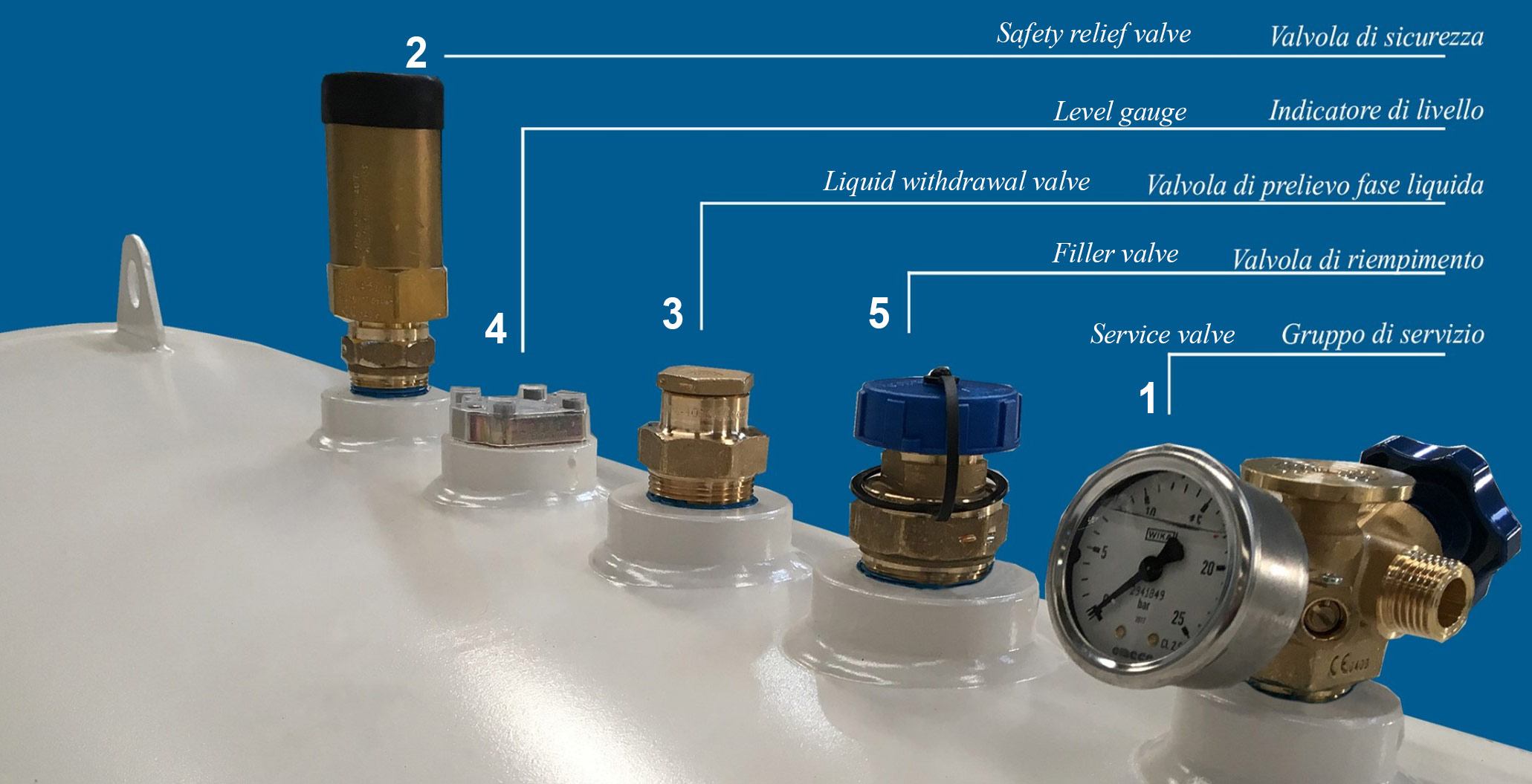

Above Ground Tanks > Safety and Service Accessories

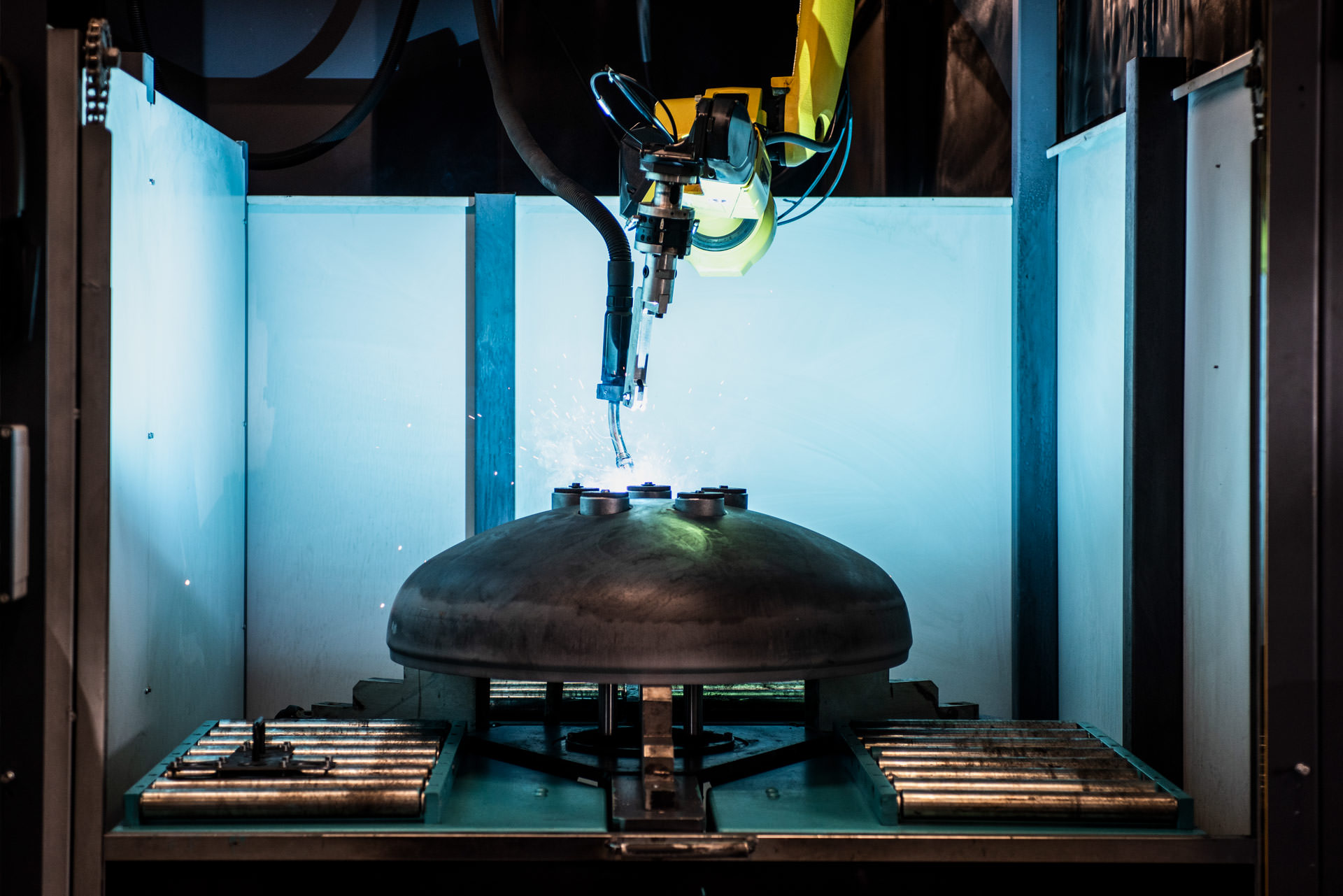

All tanks are supplied complete with safety and service accessories defined in detail by the UNI EN 14570/2014 standard. The accessories, which are indispensable for the correct operation of the LPG distribution system, are installed directly on the tank by the manufacturer. The technical characteristics of the accessories are part of the documentation attached to the identification booklet that accompanies each individual tank.